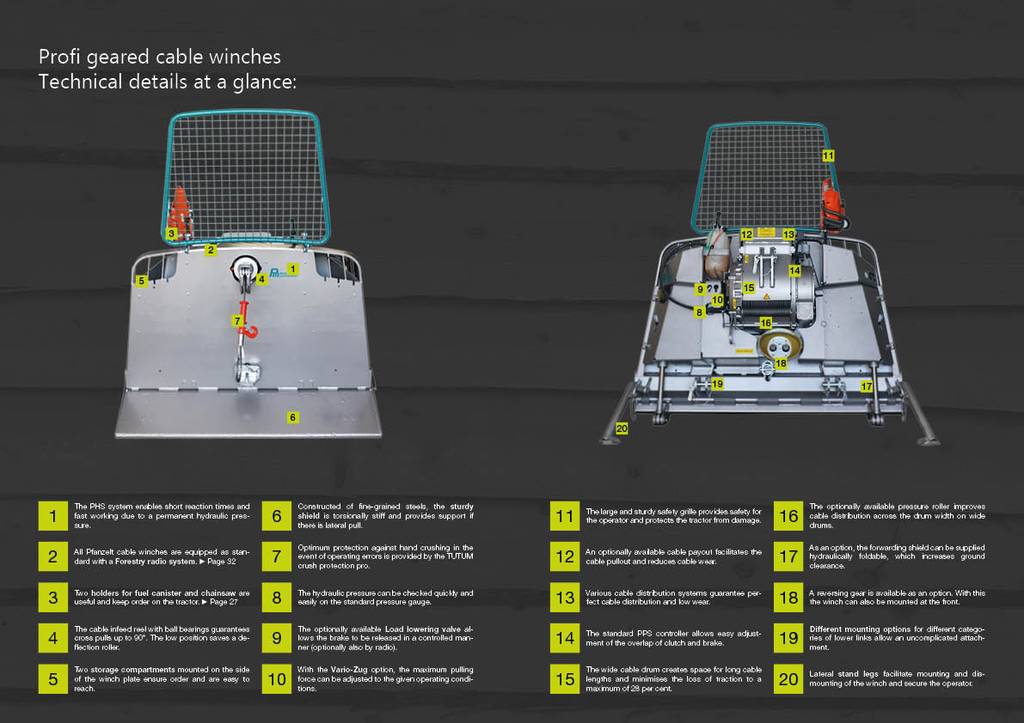

Professional geared cable winches

During the revision, great importance was attached to adopting features that have proven their worth over decades. Further developments were made, for example, in the optimisation of the hydraulic circuit for even more precise reaction times and more technical possibilities.

The new external shape offers more protection for the tractor and greater working comfort. In addition to ergonomically arranged storage compartments, access for maintenance work has also been improved.

Heavy timber recovery in flat terrain or thinning in steep mountainous areas – the requirements for a professional geared cable winch differ depending on the area of application and the available technology.

Pfanzelt Profi geared cable winches consist of a variable modular system and can thus be optimally adapted to various operating conditions. The technology is the same for all Pfanzelt cable winches. The precision worm gear used in the winch unit and the multi-disc sinter plate packs guarantee maximum reliability and durability of the winch.

More details on the Prodi geared cable winches

Winch unit

If the cable drum is aligned with the pulling direction, this enables easy cable payout and ensures low cable wear, as the cable is not fed out or wound in via several rollers in different directions. According to KWF tests, Pfanzelt cable winches have the lowest power requirement of any winch for paying out the cable. Moreover, the cable winch is mounted in an especially favourable position on the tractor in relation to centre of gravity.

The use of a cable drum with a large core diameter ensures very low tractive force loss from the top to bottom cable layer. According to independent tests by the KWF, the Pfanzelt cable winch has a maximum tractive force loss of 21% with a standard cable length.

The very low cable infeed height enables simple and comfortable operation without deflection roller.

Drive

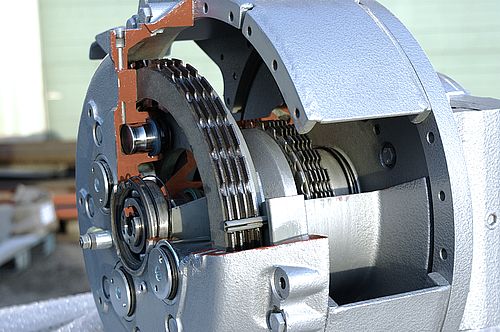

The cable winch is driven via the PTO shaft with speeds of 540, 750 or 1000 rpm. From the Cardan shaft, the drive is transmitted via a bevel gear to the precision worm gear immersed in an oil bath. This ensures very quiet running and permanent operating safety.

Multi-disc sintered plate sets are used for exact control of the braking and clutch operations and secure crossover. The complete system is protected by internal mounting.

The PHS system of the Pfanzelt Pro geared winches creates permanent hydraulic pressure in the system and thus short reaction times even after several switching operations.

PPS Controller

With the Pfanzelt PPS precision controller, which is unique on the market, the cable winch can be adapted to the respective forwarding situation. The operator can rapidly and easily adjust the crossover of the clutch and brake by preselection. This offers maximum operating comfort and the highest degree of working safety.

Cable distribution with cable infeed brake

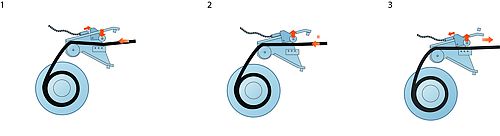

The cable is always kept taut when drawn in, even if the trunk starts to slip or the cable is loose: all made possible by the Pfanzelt cable infeed brake. A cylinder presses the cable when it is drawn in with a brake roller against the brake block. The cylinder force is selected so that the cable can only be pressed against the brake block when it is in an unloaded state. When the cable is paid out, the brake opens completely.

Position 1 The cable infeed brake is actuated by activating the Pull function

Position 2 As soon as the cable is drawn in under load, the cable infeed brake opens

Position 3 During cable payout, the cable infeed brake opens completely and thus does not obstruct cable payout.

Cable payout

The Pfanzelt cable payout has been developed to increase operating comfort and to improve the cable winding quality on the cable drum. The cable payout device built into the pivoting arm of the cable distributor has a hydraulic drive and is electrically actuated. As soon as the cable payout is activated, the cable is pressed firmly against the cable roll via several flexibly mounted pressure rollers over a large radius. Due to the special structure and correspondingly large contact area of the pressure rollers on the cable, the operability of the device is not impaired by soiling or cable damage.

Stacking shield

Pfanzelt geared cable winches are equipped with an especially robust shield made of high strength fine grained steel to create a torsion-resistant box. The resulting wedge form is able to reliably absorb even lateral pulling forces, giving many years of robust service. Laterally actuated parking supports ensure that the cable winch can be conveniently attached or removed the tractor and help prevent accidents.

Wireless control

In addition to the usual functions (pull, short release, release, continuous release, stepless engine throttle adjustment), the standard modern radio system also supports engine start/stop and an emergency call system on request.

The cable winch is equipped with HBC radio control as standard.

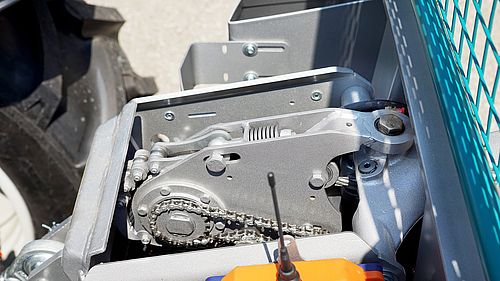

Offset gearbox

Pfanzelt cable winches with a wide cable drum can be equipped with an offset gearbox to provide a centred drive (standard equipment in some models). This is also recommended for use with tractors with an non-centred PTO stub. An offset gearbox with direction of rotation reversal can also be provided for front-and rear-mounting.

Constant traction (models P163K, P173K and 273K)

The Pfanzelt winch models P163K, P173K and P273K have a constant pulling force. This means that the winch always operates with the same force when pulling in. The usual loss of tractive force is

excluded.

This offers a higher safety level and greater ease of use, as thinner forest cables can be used, for example. The operator can thus always work with the maximum pulling force.

Auxiliary cable winch

The new auxiliary cable winch for Pfanzelt Profi geared cable winches makes off-road cable winch operation easier. In this process, operation is both simple and effective. The system is ergonomically operated by radio control.

- Pulling force: 400 kg

- Cable length: 240 m, plastic rope

- Freewheel for fast rope outout during the arrangement

- Automatic unwinding when retracting the forwarding cable

- Rope infeed brake

- Removable rope drum for easy removal of the material in between

- Incl. deflection pulley, tree strap

Quick to set up, immediately ready for operation:

- connect the end of the very lightweight auxiliary cable to the traction cable

- Activate freewheeling to easily extend the auxiliary cable

- Attach the deflection pulley at the end of the cable route to a tree

- Hook the auxiliary rope and allow the pull cable to extend

Technical specs for single drum winches

| Single drum cable winches | P163K (constant traction) | P172 | P173K (constant traction) | P186 | P1102 |

|---|---|---|---|---|---|

| Customize your machine | Configurator | Configurator | Configurator | Configurator | Configurator |

| Traction in lower cable layer | 61 kN | 72 kN | 72 kN | 86 kN | 102 kN |

| Traction in upper cable layer | 61 kN | 56 kN | 72 kN | 62 kN | 78 kN |

| Average cable speed at

540 rpm |

0.43 m/s | 0.57 m/s | 0.43 m/s | 0.43 m/s | 0.43 m/s |

| 750 rpm | 0.60 m/s | 0.80 m/s | 0.60 m/s | 0.60 m/s | 0.60 m/s |

| 1,000 rpm | 0.80 m/s | 1.05 m/s | 0.80 m/s | 0.80 m/s | 0.80 m/s |

| Maximum cable capacity | Ø 11 mm x 174 m | Ø 12 mm x 138 m | Ø 12 mm x 138 m | Ø 13 mm x 158 m | Ø 14 mm x 121 m |

| Stacking shield width (standard) | 1,800 mm | 1,800 mm | 2,000 mm | 1,800 mm | 1,800 mm |

| 3-point hitch category | 1 and 2 | 1 and 2 | 2 and 3 | 2 and 3 | 2 and 3 |

| Controller | Electrical pressure sensing control with immersed armature solenoid valve | ||||

| Drive | Mechanical via bevel gear | ||||

| Clutch | Multi-disc sintered plate set, self-adjusting | ||||

| Brake | Multi-disc brake plate linings | ||||

| Wireless control system | HBC FSE 510 patrol T | ||||

| Mechanical cable distribution | |||||

| Cable infeed brake | |||||

| PHS controller | |||||

| Pfanzelt PPS precision control | |||||

| Cable payout | optional | optional | optional | ||

| Protective grille as per accident prevention regulations (UVV) | |||||

| Cardan shaft | |||||

| Centred drive | |||||

| Weight (without cable) | 616 kg | 625 kg | 650 kg | 645 kg | 650 kg |

| Recommended tractor power | approx. 40 – 90 kW | approx. 40 – 90 kW | approx. 70 – 120 kW | approx. 55 – 100 kW | approx. 70 – 120 kW |

| Accessories | |||||

| Stacking shield widths | up to 2,400 mm | up to 2,400 mm | up to 2,400 mm | up to 2,400 mm | up to 2,400 mm |

| Hydraulic folding shield | optional | optional | optional | optional | optional |

| Proportional brake control | optional | optional | optional | optional | optional |

| Vario traction: Adjustable tractive force | – | optional | – | optional | optional |

| Automatic cable payout via cross spindles | – | – | – | optional | optional |

| Cable payout | optional | optional | optional | ||

| Centred drive with direction of rotation reversal | optional | optional | optional | optional | optional |

| Treuil de récupération pour une utilisation sur des pentes raides | optional | optional | optional | optional | optional |

| Anti-tilt system (AKS 2515 Mini_P) | optional | optional | optional | optional | optional |

Technical specs for double drum cable winches

| Double drum cable winches | P260 AKTION | P272 | P273K constant traction | P285 | P2102 |

|---|---|---|---|---|---|

| Customize your machine | Configurator | Configurator | Configurator | Configurator | Configurator |

| Traction in lower cable layer | 2 x 60 kN | 2 x 72 kN | 2 x 72 kN | 2 x 85 kN | 2 x 102 kN |

| Traction in upper cable layer | 2 x 42 kN | 2 x 58 kN | 2 x 72 kN | 2 x 61 kN | 2 x 78 kN |

| Average cable speed at

540 rpm |

0.43 m/s | 0.43 m/s | 0.43 m/s | 0.43 m/s | 0.43 m/s |

| 750 rpm | 0.60 m/s | 0.60 m/s | 0.60 m/s | 0.60 m/s | 0.60 m/s |

| 1,000 rpm | 0.80 m/s | 0.80 m/s | 0.80 m/s | 0.80 m/s | 0.80 m/s |

| Maximum cable capacity | 2 x Ø 11 mm x 88 m | 2 x Ø 12 mm x 102 m | 2 x Ø 12 mm x 138 m | 2 x Ø 13 mm x 129 m | 2 x Ø 14 mm x 100 m |

| Stacking shield width (standard) | 1,800 mm | 2,000 mm | 2,000 mm | 2,000 mm | 2,000 mm |

| 3-point hitch category | 1 and 2 | 2 and 3 | 2 and 3 | 2 and 3 | 2 and 3 |

| Controller | Electrical pressure sensing control with immersed armature solenoid valve | ||||

| Drive | Mechanical via bevel gear | ||||

| Clutch | Multi-disc sintered plate set, self-adjusting | ||||

| Brake | Multi-disc brake plate linings | ||||

| Wireless control system | HBC patrol D | ||||

| Mechanical cable distribution | optional | ||||

| Cable infeed brake | optional | ||||

| PHS controller | – | ||||

| Pfanzelt PPS precision control | – | ||||

| Protective grille as per accident prevention regulations (UVV) | |||||

| Cardan shaft | |||||

| Centred drive | |||||

| Weight (without cable) | 590 kg | 795 kg | 850 kg | 850 kg | 850 kg |

| Recommended tractor power | approx. 55 – 100 kW | approx. 70 – 120 kW | approx. 100 – 150 kW | approx. 100 – 150 kW | approx. 100 – 150 kW |

| Accessories | |||||

| Shield widths | up to 2,200 mm | up to 2,400 mm | up to 2,400 mm | up to 2,400 mm | up to 2,400 mm |

| Hydraulic folding shield | optional | optional | optional | optional | optional |

| Proportional brake control | – | optional | optional | optional | optional |

| Vario traction: Adjustable tractive force | – | optional | – | optional | optional |

| Cable payout | – | optional | optional | optional | optional |

| Centred drive with direction of rotation reversal | optional | optional | optional | optional | optional |

| Retrieval winch for use on steep slopes | optional | optional | optional | optional | optional |

| Anti-tilt system (AKS 2515 Mini_P) | optional | optional | optional | optional | optional |

Questions? Contact us!

(Service in English)

Danielle Denis

819-313-7081

sales@gesproequipement.com

Administration and Sales

Sylvain Vouligny

819-372-6392

admin@gesproequipement.com