S-line remote controlled winch

Until a few years ago, only professional operations could afford geared cable winches because of the small production runs and heavy duty design. All this has changed since the introduction of the new Pfanzelt S-line cable winch series. With the S-line cable winch, Pfanzelt now offers geared cable winches especially designed for semi-professional contractors and tree farmers with an attractive price/performance ratio. The design is the same as with the larger models, only the dimensions have been rescaled to match the size of the usually smaller tractors.

More details on the S-line remote controlled winches

Winch unit with stacking shield

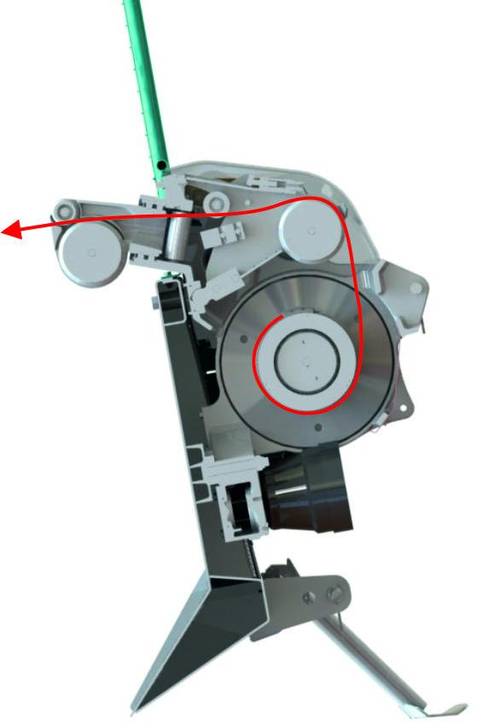

Winch unit

The alignment of the cable drum in the pulling direction enables easy cable payout and ensures low cable wear, as the cable is not fed out and wound in via several rollers in different directions. According to KWF tests, Pfanzelt cable winches have the lowest power requirement of any winch for paying out the cable. Moreover, the cable winch is mounted in an optimum position on the tractor in relation to centre of gravity.

Stacking shield

Pfanzelt S-line geared cable winches are equipped with an especially robust stacking shield made of high strength fine grained steel to create a torsion-resistant box. The resulting wedge form is able to reliably absorb even lateral pulling forces, giving many years of robust service. Laterally actuated parking supports ensure that the cable winch can be conveniently attached or removed the tractor, preventing accidents.

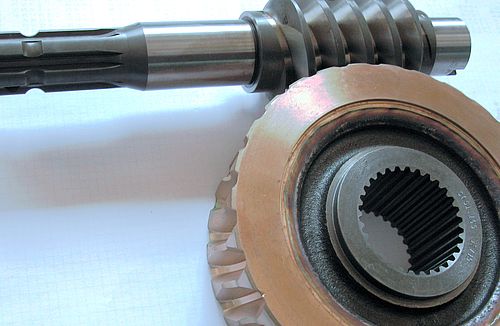

Transmission

The cable winch is driven via the PTO shaft with speeds of 540, 750 or 1000 rpm. From the Cardan shaft, the drive is transmitted via a bevel gear to the precision worm gear immersed in an oil bath. This ensures very quiet running and permanent operating safety.

Multi-disc sintered plate sets are used for exact control of the braking and clutch operations and secure crossover. The complete system is protected by internal mounting.

Minimum tractive power loss

The use of a cable drum with a large core diameter ensures very low tractive force loss from the top to bottom cable layer. According to independent tests by the KWF, the S-line cable winch has a maximum tractive force loss of 21% with a standard cable length. The very low cable infeed height enables simple and comfortable operation without deflection pulley.

PPS Controller

With the Pfanzelt PPS precision controller, which is unique on the market, the cable winch can be adapted to the respective forwarding situation. The operator can rapidly and easily adjust the crossover of the clutch and brake by preselection. This offers maximum operating comfort and the highest degree of working safety.

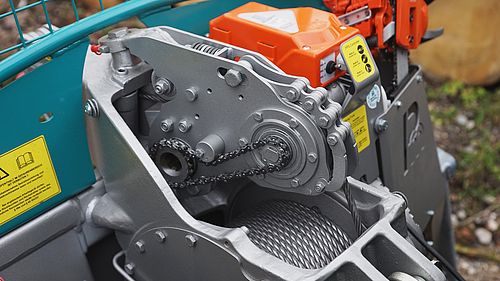

Cable infeed brake (option)

The cable is always kept taut when drawn in, even if the trunk starts to slip or the cable is loose: all made possible by the Pfanzelt cable infeed brake. A cylinder presses the cable when it is drawn in with a brake roller against the brake block. The cylinder force is selected so that the cable can only be pressed against the brake block when it is in an unloaded state. When the cable is paid out, the brake opens completely.

Cable payout (option)

The Pfanzelt rope payout was developed to facilitate use. The decoiling device installed in the swivel arm of the cable distribution is mechanically driven and hydraulically switched. The cable is firmly pressed against the cable pulley over a large radius by several flexibly suspended pressure rollers. Due to the large contact surface, functionality is ensured despite contamination or cable damage.

Load lowering valve (option)

Pfanzelt S-line geared cable winches can be equipped with a load lowering valve. This means that a cable under strain can be gradually released and lowered. This feature is essential for safety felling work In order to prevent disruptions, the cable winch operates with a separate oil circuit with filter unit that is fed via a radial piston pump and operates all hydraulic functions.

Wireless remote control as standard

The radio control is standard equipment

The S-line cable winches are equipped with a radio control system for safe, comfortable, and gentle working. The operator is thus not in the danger zone and can detect obstacles.

The safety update

The new radio control decouples Pull and Release. The command Pull is now activated via a pushbutton.

All functions at a glance

- Pull (via pushbutton)

- Release, short release (via rocker arm)

- infinitely variable motor speed adjustment

- Emergency stop

- PPS-switchover via radio

Technical specs

| S150 | S160 | S172 | |

|---|---|---|---|

| Customize your machine | Configurator | Configurator | Configurator |

| Traction in lower cable layer | 50 kN | 60 kN | 72 kN |

| Traction in upper cable layer | 40 kN | 47 kN | 56 kN |

| Standard cable lengths (high density forestry cable with sliding hooks) |

Ø 10 mm x 70 m | Ø 11 mm x 70 m | Ø 12 mm x 60 m |

| Professional forestry wireless control | Radio system with toggle switch, pushbutton and emergency stop button | ||

| Pfanzelt PPS precision controller | |||

| Stacking shield width (standard) | 1,500 mm | 1,500 mm | 1,800 mm |

| Weight (without cable) | approx. 470 kg | approx. 490 kg | approx. 580 kg |

| Recommended tractor power | max. 40 kW | approx. 30 – 60 kW | approx. 40 – 90 kW |

| Accessories | |||

| Cable distribution with cable infeed brake | optional | optional | optional |

| Long cable package (incl. cable distributor with cable infeed brake) |

optional Ø 10 mm x 110 m |

optional Ø 11 mm x 100 m |

optional Ø 12 mm x 90 m |

| Cable payout | optional | optional | optional |

| PTB automated drum trailing brake | optional | optional | optional |

| Load lowering valve | optional | optional | optional |

| Bevel gear for front attachment | optional | optional | optional |

| Shield width 1,800 mm | – | optional | |

| Shield width 2,000 mm | – | optional | optional |

| Shield width 2,200 mm | – | optional | optional |

| Retrieval winch for use on steep slopes | optional | optional | optional |

Questions? Contact us!

(Service in English)

Danielle Denis

819-313-7081

sales@gesproequipement.com

Administration and Sales

Sylvain Vouligny

819-372-6392

admin@gesproequipement.com