Pm Trac 8-wheel-systems

More details on Pm Trac 8-wheel

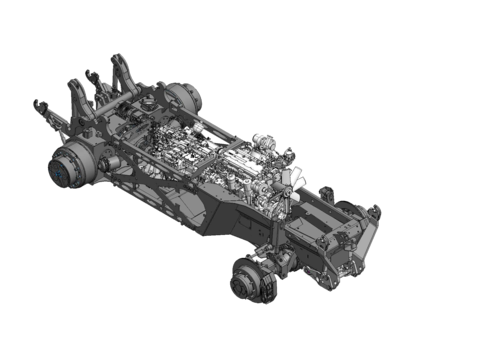

The chassis

From the outside, the Pm Trac hardly looks any different. However, much has been further developed on the chassis, and new components are used. The chassis is built over a frame in which the individual units are installed. The biggest change to the chassis concerns the transaxle. The transmission and rear axle unit was previously purchased from ZF. With the new series, Pfanzelt produce the unit themselves – the variaDRIVE transmission as well as a new, planetary-driven rear axle from Pfanzelt are used. The Pm Trac Generation 38 is now based on an almost 100% Pfanzelt tractor chassis. This enables the complete adaptation of all components to heavy-duty use in forestry and as a multipurpose tractor. The days of using components from agricultural tractors are over. The Pm Trac plays in a new league.

variaDRIVE

The comfortable and powerful handling corresponds to that of familiar power-split transmissions. However, additional comfort is offered when changing the direction of travel. This operates more gently and quickly. In this way, it is comparable to that of a hydrostat. The new transmission is also efficient and performance-oriented thanks to the three travel ranges in forward drive and two travel ranges in reverse drive.

- Top speed 40/50 km/h

- Motor gear management

- No switching of clutches in shunting mode up to approx. ±7 km/h

- Reduction of the engine speed when the final speed is reached

- Individual preselection of maximum speed for special applications (for example, forestry milling)

Implement and mounting compartments

In addition to the rear mounting compartment which is positioned with a favourable centre of gravity above the rear axle, the Pm Trac has a three-point implement compartment on the front and rear. Optional front loader consoles are available.

- Rear compartment

- Rear three-point linkage

- Front three-point linkage

- Front loader console

Pfanzelt System for Attachment (PSA)

The relocation of the cab to the centre of the vehicle means that additional implements can be mounted in the tail attachment bay by means of the Pfanzelt System for Attachment (PSA); as a result the attachments are directly over the rear axle.

Via a special quick conversion system, attachments can be changed without requiring tools in a very short time. For example, it now takes less than 20 minutes to attach or remove a crane or cable winch.

Road travel

A roadworthy transmission technology and a standard road approval for 50 km/h allow the operator to approach or change locations quickly and without additional transport technology. The vehicle can also be driven on public roads in combination with a forwarding trailer or a trailer chopper.

The lighting system and fenders required for road travel can easily and quickly be converted for forestry operations. The four fenders, which are mounted as a pluggable system, are taken off the vehicle. The side indicators and front lights are concealed behind protective devices.

XXL cab

The tractor cab developed by Pfanzelt with pneumatic suspension enable smooth and vibration-free operation.

The view over the working environment is further extended by 7 m2 of window area. The driver has an even better view of his working zone, this means less stress and increasing safety. The driver has a relaxed and ergonomic sitting and working position on the operator stand that can now can be turned through 350° by electric motor. The intelligent machine controller which is operated via a touch screen from the seat – also saves the individual preferred settings for different drivers.

The Pfanzelt XXL cab has been especially created with the demands of our customers in mind – low vibrations when working in standing timber yet with maximum comfort when driving at 50 km/h on public roads.

All operating and monitoring functions are mounted on the seat and therefore always in the operator’s field of vision.

An additional control panel for on-road driving is provided next to the steering wheel. All key parameters are conveniently displayed in driver’s field of vision.

Unique in the forestry industry and essential for municipal use is the possibility to install a passenger seat in the driver’s cab as an option.

For forestry work, the steering column is simply and rapidly folded to one side.

The new machine software

The intelligent machine control system, which is operated via a touchscreen monitor on the seat, allows presettings to be stored for four operators. A Pfanzelt default user, which cannot be modified, is also stored.

An additional operating terminal for road travel is located next to the steering wheel. All important parameters are displayed there in the driver’s best possible view.

The new command centre on the rotating operator station

- Driver management for four drivers incl. individual assignment of joysticks and control levers

- Presets for hydraulic control units, crane functions, and auxiliary pumps

- PTO management

- Engine speed management

- Adjustment of the driving characteristics

Excerpt from the extensive menu navigation

- Adapted to the driver; he can individually preselect the assignment of all joystick functions and operating levers for hydraulic control units at the operator station, and save them in the driver management system.

- The hydraulic management allows presetting of all crane functions (including flow regulation, adjustment of characteristics of individual hydraulic functions and ramps).

- In addition to the preselection of speed and start-up characteristic, an automatic switch-on and switch-off can also be preset in the PTO management.

Service friendly

Pfanzelt’s carefully designed service concept begins with easy access to the radiator and engine compartment for cleaning. The vehicle cab can be tipped up for easy access to the remaining machinery compartment. The loading crane and cable winch can be removed in a matter of minutes, exposing the remainder of the chassis.

The floor pan of the tractor can be additionally opened via a cable winch. This means that one person can safely work on his own.

Create an 8-wheel system thanks to forwarding trailers

In this combination the Pfanzelt Professional P17 forwarding trailer boasts a payload of 15 metric tons and a drive force of 6.1 metric tons. As a result the 8-wheel system generates a thrust of 16.1 metric tons. This means the vehicle can also cope with challenging terrain and it keeps damage to substrate to a minimum. The Pm Trac electronically and fully automatically controls the forwarding trailer’s drive speed. Operators can make any required adaptations. Consequently, it is possible to adjust the lead or lag.

The range of the steerable draw bar totals 68 degrees to thus make the combination agile and enable manoeuvring in confined spaces.

The electronic terminal features a large display to monitor the drive system and all important operating states. The terminal also enable a configuration of different adjustment options.

Using the cable winch with the forwarding trailer

If required, the remote-controlled, dual-drum cable winch that has been installed at the rear below the crane remains fully functional, even with attached forwarding trailer. Consequently, the unit provides an unrestricted attachment of tree trunks outside the crane’s reach using cables as well as felling with cable winch support.

Technical spec Pm Trac 8-wheel

| Pm Trac 3820 | Pm Trac 3825 | Pm Trac 3830 | ||

|---|---|---|---|---|

| Customise now | Configurator | Configurator | Configurator | |

| Engine | In-line six-cylinder turbo diesel engine with electronic control, common rail, EU V exhaust stage, Cleanfix MC switchover fan | |||

| Output (at 2,100 rpm as per ISO14396) | 151 kW/ 205 hp | 186 kW/ 253 hp | 215 KW/ 292 hp | |

| Cylinder capacity | 7,4 ltr. | 7,4 ltr. | 7,4 ltr. | |

| Transmission | variaDRIVE continuously variable 0-50 km/h

Continuously variable, power-split transmission with cruise control function, engine transmission management, three forward travel ranges, two reverse travel ranges, max. travel speed at lowered engine speed (approx. 1,800 rpm), active standstill control |

|||

| Front axle | Hydro-pneumatically suspended thrust tube axle with automatic level control, electro-hydraulically switchable differential lock, central front axle drive, integrated constant-velocity steering cylinder, axle automatically locked when crane is stationary | |||

| All-wheel drive | All-wheel & differential lock management | |||

| Steering | Hydrostatic steering, steering column can be folded away when working, joystick steering | |||

| Brakes | Two-circuit air brake

Rear axle: Dry drum brake, pneumatically-actuated parking brake via Tristop cylinder with integrated trailer test position, single-wheel brake Front axle: Dry disc brake incl. integrated Opti-Stop front axle brake |

|||

| PTO | Switchable PTO 540E/ 750/ 1000 rpm (optional 1000E/1000/1450 rpm)

PTO connection 1 3/8″ pluggable PTO shaft, electro-hydraulic switchable wet multi-plate clutch, PTO automatic, PTO management, adjustable start-up mode, automatic switch-off (speed-dependent) |

|||

| Hydraulics | Hydraulic system with axial piston pump, controlled load sensing, hydraulic oil cooler

Flow rate/operating pressure: 160 l/min / 210 bar (option: 200 l/min) |

|||

| Electronics | CAN BUS system: Central control and monitoring of engine, gear unit, and auxiliary control units at the operator station Integrated functions for crane settings, all-wheel drive, differential, steering Four different driver settings can be stored, additional Pfanzelt default setting |

|||

| Front power lift | max. lifting force 35 kN, double-action | |||

| rear power lift | Max. lifting force 82 kN, external lifting cylinder with float position, switchable to double-acting for lifting and pushing |

|||

| Front loader | Flange points on the integrated support frame for mounting front loader consoles | |||

| Rear attachment bay | Pfanzelt system pick-up (PSA), vehicle support frame for stabilisation, block design | |||

| Cab | Large volume, air-suspended cabin with all-round visibility (over 7 m2 window area), two large roof windows, safety cabin according to ISO standards (ROPS) | |||

| Operator stand | Air-suspended swivel seat with seat heating, rotation by electric motor by 340° | |||

| Ventilation | Powerful heater and air-conditioning system with three-speed blower, incl. automatic climate control system | |||

| Additional standard equipment | Removable fenders, storage box, pneumatically controlled step, fire extinguisher | |||

| Dead weight / permitted max. weight | Depending on equipment/14 t | |||

|

Pm Trac 8-wheel system forwarding trailer |

Forwarding trailer Profi P17 | Forwarding trailer logLINE L19 | ||

|

Loading cross section |

3,52 m² | 3,5 – 4,0 m² | ||

|

Payload in forests |

15,0 t | 17,0 t | ||

|

Permitted max. weight on public roads |

17,0 t | 19,0 t | ||

|

Deadweight |

2,5 t | 3,5 t | ||

|

Tyres |

600/50-22.5 | 600/50-22.5 | ||

|

Drive |

powerDRIVE 4-wheel hub drive including electronic control unit |

powerDRIVE 4-wheel hub drive including electronic control unit |

||

|

Drive power |

6,1 t | 6,1 t | ||

|

Drive speed |

4,1 km/h |

4,1 km/h |

||

Questions? Contact us!

(Service in English)

Danielle Denis

819-313-7081

sales@gesproequipement.com

Administration and Sales

Sylvain Vouligny

819-372-6392

admin@gesproequipement.com