Skip to main content

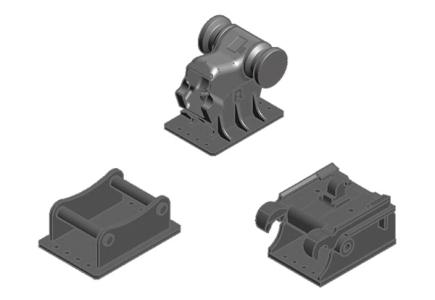

Forestry mulching heads for 9-16 T excavators with fixed hammers

Forestry mulcher for excavators from 9 to 16 Tons. Ideal for your forest clearing or brush cutting work.

Ideal for intensive clearing and deforestation work, the fixed-hammer forest shredders XYLOR PE stand out for their ability to precisely grind large volumes. Their adaptation to excavators weighing from 9 to 16 tons provides them with better maneuverability and a greater reach, allowing precise work in difficult and steeply inaccessible areas.

An essential tool for clearing existing vegetation, these grinding heads are significant allies for maintaining rural spaces, creating firebreaks, and forestry paths.

The fixed carbide-tipped hammers are arranged in a helical pattern on the rotor to better distribute power and thus limit wear. They deeply attack brambles, bushes, and branches with a diameter of 140 mm in a single pass.

For even greater efficiency, the XYLOR PE forest shredder is equipped with two lines of counter-knives to refine the shredding to the maximum.

To optimize their performance and productivity, all our forest shredders have an HBC (Hydraulic Block Control) system to regulate the flow by limiting pressure for a progressive braking of the rotor.

Known for their efficiency as well as their robustness, our excavator-mounted forest shredders are the ideal grinding tools for intensive vegetation shredding tasks.

An essential tool for clearing existing vegetation, these grinding heads are significant allies for maintaining rural spaces, creating firebreaks, and forestry paths.

The fixed carbide-tipped hammers are arranged in a helical pattern on the rotor to better distribute power and thus limit wear. They deeply attack brambles, bushes, and branches with a diameter of 140 mm in a single pass.

For even greater efficiency, the XYLOR PE forest shredder is equipped with two lines of counter-knives to refine the shredding to the maximum.

To optimize their performance and productivity, all our forest shredders have an HBC (Hydraulic Block Control) system to regulate the flow by limiting pressure for a progressive braking of the rotor.

Known for their efficiency as well as their robustness, our excavator-mounted forest shredders are the ideal grinding tools for intensive vegetation shredding tasks.

On video : Forestry mulching heads for 9-16 T excavators with fixed hammers

Main Features

- For excavators from 9 to 16 Tons.

- Helical rotor with fixed carbide points hammers.

- 2 counter hammers lines in ”U” shape for an optimal shredding.

- Rotor electronically balanced to real rotation speed for more durability.

- HBC system (Hydraulic Block Control) allowing the hydraulic flow regulation, limits the pressure and allows rotor progressive braking.

- Piston engine with 2-position displacement and drainage.

- Front protection with chains to prevent projections.

- Casing for the hydraulic motor.

- Lateral transmission through toothed belts.

- Support pads with interchangeable and anti-wear material.

- Anti-jet sheath for hydraulic hoses.

- Hydraulic rear door in option.Requires a 2nd dual-acting hydraulic line on the carrier.

Technical characteristics

| Model |

| Excavator weight |

| Rotor type |

| Number of hammers |

| Counter-knives line |

| Crushing width |

| Shredding Ø |

| Helical rotor |

| Rotor Ø (with tools) |

| Gear motor power |

| Drain line |

| Drive |

| Oil flow recommended Oil flow max. |

| Maximum pressure |

| Dimensions (L x W x H) without hitch |

| Weight |

| XYLOR 1014 PE |

| 9 to 16 Tons |

| Fixed hammers |

| 18 |

| 2 lines |

| 1000 mm |

| 140 mm |

| Yes |

| 420 mm |

| 2 postitions : 35 or 46 cm³ |

| Yes |

| 4 belts |

| 2-position displacement of 85 or 110 l/min 240 l/min |

| 250 bar |

| 0,86 x 1,35 x 0,65 m |

| 505 kg |

| XYLOR 1214 PE |

| 9 to 16 Tons |

| Fixed hammers |

| 24 |

| 2 lines |

| 1200 mm |

| 140 mm |

| Yes |

| 420 mm |

| 2 postitions : 35 or 46 cm³ |

| Yes |

| 4 belts |

| 2-position displacement of 85 or 110 l/min 240 l/min |

| 250 bar |

| XYLOR 1414 PE |

| 9 to 16 Tons |

| Fixed hammers |

| 27 |

| 2 lines |

| 1400 mm |

| 140 mm |

| Yes |

| 420 mm |

| 2 postitions : 35 or 46 cm³ |

| Yes |

| 4 belts |

| 2-position displacement of 85 or 110 l/min 240 l/min |

| 250 bar |