Skip to main content

Firewood processor : XYLOG 410

Wood processors with Ø 1000 mm circular blade for logs up to 410 mm of diameter.

The XYLOG 410 firewood processor is the ideal equipment to confidently start producing log wood. Its circular saw blade with carbide teeth easily and quickly handles all types of wood, even dry and very hard, up to 410 mm in diameter. Perforated, it minimizes noise during cutting. Designed to be sharpened approximately every 5000 cubic meters, maintenance and upkeep are significantly reduced.

Versatile, this processor allows choosing the cutting length between 200 to 500 mm.

For the splitting operation, RABAUD chose to offset its splitter for a better placement of the log in the splitting channel. The splitting cross adjusts in height hydraulically to center the log for equal-sized logs. It is also interchangeable: 2, 4, 6, or 8 splits are possible to choose the log diameter, optimize production, or adapt to the type of wood.

The large-diameter pusher covers the entire surface of the log for better distribution of power, which automatically varies according to the wood resistance (up to 16 tons).

Wood evacuation is done by a hydraulic or manual conveyor allowing unloading at height into a skip and, depending on the model, can be oriented to the right or left for more versatility.

Devoid of any electronics, interventions for machine maintenance can be performed directly by the operator.

For optimal working comfort, all controls are centralized, allowing the operator to stay at a single control station and increase productivity.

Versatile, this processor allows choosing the cutting length between 200 to 500 mm.

For the splitting operation, RABAUD chose to offset its splitter for a better placement of the log in the splitting channel. The splitting cross adjusts in height hydraulically to center the log for equal-sized logs. It is also interchangeable: 2, 4, 6, or 8 splits are possible to choose the log diameter, optimize production, or adapt to the type of wood.

The large-diameter pusher covers the entire surface of the log for better distribution of power, which automatically varies according to the wood resistance (up to 16 tons).

Wood evacuation is done by a hydraulic or manual conveyor allowing unloading at height into a skip and, depending on the model, can be oriented to the right or left for more versatility.

Devoid of any electronics, interventions for machine maintenance can be performed directly by the operator.

For optimal working comfort, all controls are centralized, allowing the operator to stay at a single control station and increase productivity.

On video : Firewood processor : XYLOG 410

Main Features

- Maximum cutting diameter : 410 mm

- Quick and easy adjustment of the cutting length : 200, 250, 300, 330, 350, 400, 450 or 500 mm.

- Cutting through circular saw with carbide teeth Ø 1000 mm driven by 5 belts.

- 4 possible splitting wedges : 0/2/3 splits, 2/4 splits, 2/6 splits, 2/8 splits.

- Hydraulic adjustment of the splitting wedge.

- Automatic hydraulic adjustment of the splitting power up to 16 Tons.

- Hydraulic clamp to hold the log during the cutting.

- Deported splitting zone with “V” to properly center the logs.

- Simple operation without any electronics (except TH+).

- 4 m or 4.50 m long discharge conveyor on TH version, with metalbars, made up of several strips for an easy and cost-saving maintenance.Strips are 350 mm wide on TM version and 500 mm wide on TH version.

- Hydraulic tilting of the discharge conveyor +/- 10° on TH version (1.25 m wide).

- Foldable conveyor for transportation and adjustable in height , manual witha winch on TM version, hydraulic for the TH version.

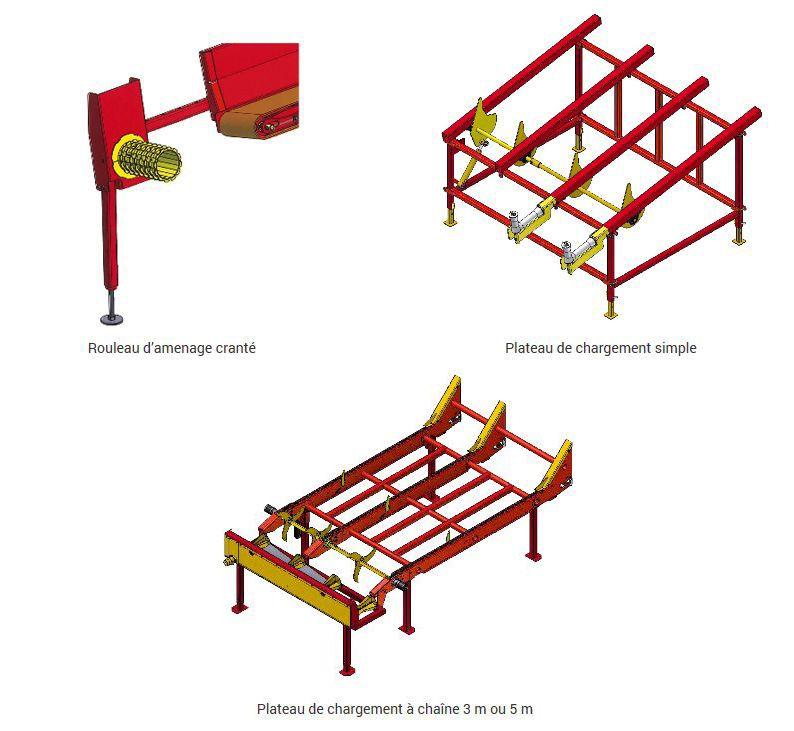

- Options : loading conveyor, electric motor, wedge support stand.

Technical characteristics

| Model |

| Splitting power |

| Cutting Ø |

| Length of cut |

| Circular saw Ø |

| Maximum wood length |

| Wedge |

| Loading height at 40° |

| Transport dimensions (L x W x H) |

| Weight |

| Drive |

| Tractor power |

| XYLOG 410 TM |

| 16 Tons with AUTO2SPEED |

| Max. 410 mm |

| Adjustable from 200 up to 500 mm |

| 1000 mm with carbide teeth |

| 4,00 m |

| 0/2/3 chips or 2/4 chips or 2/6 chips or 2/8 chips |

| 2,85 m |

| 2,05 x 2,55 x 2,78 m |

| 1635 kg |

| PTO 540 rpm + hydraulic unit 56 L/min |

| 35 to 100 HP for drive – min. 90 HP for transport N°2 3-point linkage |

| XYLOG 410 TH |

| 16 Tons with AUTO2SPEED |

| Max. 410 mm |

| Adjustable from 200 up to 500 mm |

| 1000 mm with carbide teeth |

| 4,00 m |

| 0/2/3 chips or 2/4 chips or 2/6 chips or 2/8 chips |

| 3,13 m |

| 2,16 x 2,54 x 2,95 m |

| 1870 kg |

| PTO 540 rpm + hydraulic unit 56 L/min + 11 L/min |

| 35 to 100 HP for drive – min. 90 HP for transport N°2 3-point linkage |

| XYLOG 410 TH+ |

| 16 Tons with AUTO2SPEED |

| Max. 410 mm |

| Adjustable from 200 up to 500 mm |

| 1000 mm with carbide teeth |

| 4,00 m |

| 0/2/3 chips or 2/4 chips or 2/6 chips or 2/8 chips |

| 3,13 m |

| 2,16 x 2,54 x 2,95 m |

| 1910 kg |

| PTO 540 rpm + hydraulic unit 65 L/min + 25 L/min |

| 35 to 100 HP for drive – min. 90 HP for transport N°2 3-point linkage |