Felix 4 WD special forestry hauler

The rear section of the Felix in the 4WD version is designed for working with long timber. In the early days of mechanical timber recovery, all that was available was the cable winch. It was several years later that cranes and clam bunks were introduced, whereby the underlying machine system remained the same.

We all know that Felix is the combined machine on the forestry machinery market. However, the way how Stefan Achathaler from Adlwang in Austria uses his Felix specialist forestry tractor opens up completely new options for an effective and efficient completion of small and large forestry activities.

The four-wheeled version of the Felix is supplemented by a quick-change system for different equipment installed on the crane tip and the Nisula 500H harvester unit.

Achathaler manages company-owned and third-party woodland. For this reason, the company’s staff greatly values Felix’s on-road capabilities enabling speeds up to 40 km/h. “Consequently, we can work on two sites on a single day since we simultaneously participate in both smaller and larger projects,” Stefan Achathaler explains. “It was particularly important to us that all application areas, from strong timber felling to thinning, are covered by a single machine.” In this context, Felix’s concept was the most convincing.

More details on Felix 4-wheel

hydra2POWER

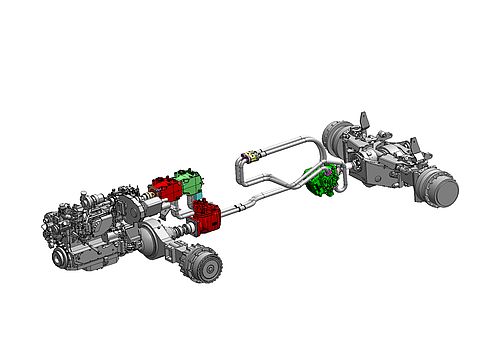

The new generation of the Felix special forestry tractors has a completely new, modern and efficient powertrain.

The new hydra2POWER combines the following features:

- powerful drive thanks to heavy duty components

- optimum traction due to permanent all-wheel drive and hydraulic longitudinal differential

- low fuel consumption thanks to modern wide angle hydraulic motors

- high degree of safety thanks to active parking control

- low maintenance costs

The hydra2POWER continuous traction drive – developed by Pfanzelt in-house – of the new Felix forestry tractor series consists of two powerful and large hydraulic pumps and motors. Each axle is thus assigned its own drive unit. No mechanical components that often require additional maintenance are required in this system. The heavy duty design of hydraulic components enables low engine revs even when driving on-road. The road cruising speed of 40 km/h is thus achieved at an engine speed of 1,600 rpm.

The permanent all-wheel drive and hydraulic longitudinal differential assure you of optimum traction and great flexibility. The driver is thus able to rely on full traction in all situations. When driving with chains or belts on only one axle, the front section of the vehicle does not lock with respect to the rear section. The result is less wear of tyres and vehicle combined with lower fuel consumption.

High efficiency and consequently low operating costs are made possible by the two 45° swivel angle hydraulic motors.

The electronic control of the traction drive allows the programming of application-specific driving characteristics. Depending on whether the vehicle is driving off or on road, acceleration, coasting during deceleration and active parking control are adjusted. The driver can thus manoeuvre precisely on steep slopes solely with the gas pedal.

Front section

Our new customers are always surprised when they see the Felix special forestry hauler for the first time. The reason is the unorthodox division of the vehicle. Thus the cab is located right at the front.

If you consider this distribution of units, you have to admit that while it may be unorthodox it is certainly logical. One the one hand, the short hood gives the driver an optimum view, on the other, due to the ideal approach angle based on the distance between the front axles and front stacking shield, no tracks are left when entering the trail.

Vehicle sections

A rear section with generous installation space was designed so that cable winches, crane and clam bunk could be fitted. This configuration prevents the machine tipping during forwarding with heavy timber in the crane or clam bunk. At the same time, due to the optimum weight distribution, it is possible to work in the most challenging terrain while minimising damage to the forest floor and fuel consumption.

Pfanzelt quick-change system

The Pfanzelt quick-change system enables a tool-free and time-optimized conversion of the stanchion cage to the clam bunk on types F and V. During conversion of the machine, add-ons can be fitted to the flat bed.

Working on a steep slope

In order to ensure optimum and safety-optimised working even on steep slopes, the roller block is hydraulically height-adjustable. Guide tubes ensure the necessary cable protection from the power unit to the cable infeed roller. Damaging the cable with the gripper is therefore impossible.

Stanchion basket tilt

In order to shift the centre of gravity upwards when driving sideways on slopes, the stanchion basket can optionally be tilted sideways.

The steering system

The Pfanzelt Felix 208 4-WD special forestry hauler is a world beater when it comes to manoeuvrability. By a skilful combination of joint and stub axle steering, previously unimaginable manoeuvring options are made possible. The steering system is an important design feature of the Felix 4WD. When driving on public roads at 40 km/h, only the articulated steering is operated by the steering wheel. During operation, the steering system is switched to joystick operation. This means that the operator can apply both articulation and stub axle steering, independently of each other. The result is unsurpassed manoeuvrability and a steering angle of 70°.

Precarious situations occur almost daily, for example when the vehicle has slipped into a ditch. If the vehicle has problems manoeuvring with pure articulation steering, the Felix can effortlessly drive out of the ditch in parallel mode. The optimum weight distribution means that even wet ground is protected when travelling in crabbing mode.

Permit for public roads

When considering the work process of a forestry machine, it is essential start the analysis at the yard and not leave until you are out in the wood. How the machine reaches the work location and how it travels from one work site to the next are also big factors in the overall economy. Does the forestry machine have to be brought to the location by a truck on a low loader or does it have a transmission system that also enables travel on public roads?

The Felix offers the flexibility of a vehicle concept that does not require any external aids to reach the work site or to change between work sites.

XXL – cab

The pneumatically sprung cabin developed by Pfanzelt enables a quiet and low-vibration work.

With more than 7 m² of glass, the view of the working environment has been further enhanced. The driver has an even better view of his working area, which facilitates work and increases work safety. The driver finds a relaxed and ergonomic seat and working position on the operator’s platform which can now be rotated electrically by 340°.

The intelligent machine control system which is operated by a monitor on the seat also allows presettings to be saved for different drivers.

The Pfanzelt XXL cabin was designed especially for the demands of our customers. Few vibrations when working in standing timber and still maximum driving comfort when driving on the road.

When working in the forest, the steering column is quickly and easily folded towards the side.

All operating and monitoring functions are mounted on the seat and are therefore always in the operator’s field of vision.

An additional operating terminal for road travel is located next to the steering wheel. All important parameters are displayed there in the driver’s best possible view.

Unique in the forestry industry and essential for use in municipal applications, there is an option of installing a passenger seat in the cab.

Service friendly

The distribution of the vehicle components requires that the engine, transmission and the main hydraulic components are installed under the cab. In spite of this, all areas that have to be accessed in the Felix specialised forestry tractor for service work can be easily reached without tools via various special service openings. In addition to the ergonomic one-man system for hydraulically opening and closing the vehicle floor plates, the cab, for example, can be hydraulically tilted open. Additional service hatches at the entrances provide side access.

Technical specs for Felix 4-wheel

| Felix 208.5 4WD F | Felix 208.5 4WD K | Felix 208.5 4WD V | |

|---|---|---|---|

| Customize your machine | Configurator | Configurator | Configurator |

| Engine | Deutz TCD 6.1 Stage V | ||

| Power (at 2,100 rpm as per ISO14396) | 133 kW/ 180 hp or 174 kW/ 236 hp | ||

| Torque | 818 Nm at 1,500 rpm/ 1,072 Nm at 1,500 rpm | ||

| No. of cylinders / cylinder capacity | 6 / 6,057 cm³ | ||

| Exhaust gas treatment | SCR catalyst, for exhaust gas treatment, performance (ISO 14396) | ||

| Tank capacity | 220 L | ||

| Transmission | Pfanzelt hydra2POWER | ||

| Specifications | Hydrostatic infinitely adjustable traction drive, 2 pumps with dual motor technology (each axle one unit), drive without Cardan shaft, hydraulic motors with wide angle technology up to 45 degrees, max. traction force approx. 142 kN at diesel engine speed of 1,600 rpm, hydrostatic direction reversal, reversing circuit (forward / reverse ), driving speed from 0-39 km/h, hydraulic spring accumulator, parking brake | ||

| Frame | Rear section frame made of fine grain steel, box structure, central spar | ||

| Telescopic central spar | – | – | |

| Loading bed | 4,440 mm length 2,070 mm width 3.2 m² loading cross-section |

–

– Without head frame |

3,240 mm/ 4,440 mm

2,070 mm width 3.2 m² loading cross-section |

| Axles | Front axle (rigid planetary axis) Kessler, load capacity 29 t Rear axle (planetary axle with stub axle) Kessler, load capacity 29 t |

||

| All-wheel drive | Permanent all-wheel drive with hydraulic longitudinal differential Electrohydraulic locking for front and rear axle |

||

| Steering | Hydrostatic steering with separate oil circuit, adjustable steering column height and inclination, steering columns folds away during forestry operations, combined steering function consisting of articulated and stub axle steering in the rear section, separately operated under field conditions via joystick, for driving on public roads via steering wheel (articulated steering only), rear steering in this case locked | ||

| Hydraulics | Pressure- & volume controlled axial piston pump with load-sensing function, performance: 200 L at 215 bar, control valves: Electrically proportionally controlled valves, managed by electronically programmable control unit, joystick (Colt type), hydraulic tank 160 L | ||

| Control valves | Electrically proportionally controlled valves, managed by electronically programmable control unit, joystick (Colt type) | ||

| Electronics | Control panel, touchbutton control integrated in operator console, functions for crane settings, cable winch, differential, steering | ||

| Cab | Large-volume, air-suspended cab with all-round visibility (over 7 m2 window area), two large roof windows at the rear and front, safety cab according to ISO standards (ROPS)

Rear window made of 12 mm mono-polycarbonate (regulation for use with cable winches) |

||

| Air suspended rotary seat with seat heater | The complete control station can be rotated through 350° by an electric motor (Grammer Actimo XL) Joystick supports on both armrests |

||

| Ventilation | Heating with 3-stage blower, automatic air-conditioning | ||

| Fire extinguisher | |||

| Lighting | 12 working floodlights integrated in cab roof | ||

| Tyres | optionally: 600/65–34″/

620/75–26″ / 710/55–34″ |

optionally: 600/65–34″/

620/75–26″ / 710/55–34″ |

optionally: 600/65–34″/

620/75–26″ / 710/55–34″ |

| Additional standard equipment | Detachable mudguards, 2 large stowage bins with integrated pneumatically operated step | ||

| Dead weight / permitted max. weight | According to equipment / 18.0 t (40 km/h) | ||

Questions? Contact us!

(Service in English)

Danielle Denis

819-313-7081

sales@gesproequipement.com

Administration and Sales

Sylvain Vouligny

819-372-6392

admin@gesproequipement.com