Skip to main content

Plain wire unwinding machine : DEROULMATIC

Unwinder / rewinder for plain wires equipped with 1 to 5 rows of plain wires. Ideal for fencing.

RABAUD, a global leader in fence mechanization, offers equipment to unwind and wind smooth wires in vineyards, the DEROULMATIC PX. The chassis can accommodate 1 to 5 unwinding trays to unwind up to 5 rows in a single pass. All trays of the smooth wire unwinder are adjustable in width and height, and retractable, allowing adaptation to your vineyards.

The tractor-mounted unwinding and winding machine optionally includes a tray to unwind a drip hose at the base of your rows, providing greater versatility. A hydraulic winding option is also adaptable, allowing winding up to 2 wire coils.

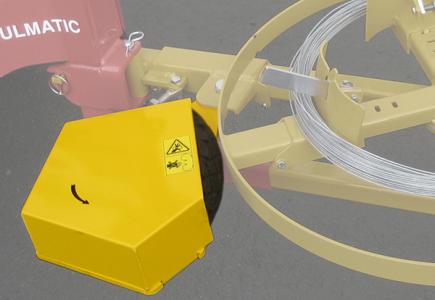

The coils are mounted on adjustable supports, requiring no diameter constraints. A locking system keeps them in place throughout the entire operation. For controlled handling, a brake system slows down the unwinding, ensuring optimal wire tension during your trellising.

Versatile and easy to use, this trellising machine saves time and effort in your small or large-scale trellising projects.

The tractor-mounted unwinding and winding machine optionally includes a tray to unwind a drip hose at the base of your rows, providing greater versatility. A hydraulic winding option is also adaptable, allowing winding up to 2 wire coils.

The coils are mounted on adjustable supports, requiring no diameter constraints. A locking system keeps them in place throughout the entire operation. For controlled handling, a brake system slows down the unwinding, ensuring optimal wire tension during your trellising.

Versatile and easy to use, this trellising machine saves time and effort in your small or large-scale trellising projects.

On video : Plain wire unwinding machine : DEROULMATIC

Main Features

- The machine is able to unwind 1 up to 5 plain wire coils in one pass.

- The machine can wind 2 plain wire coils thanks to the option hydraulic winding system to mount on the plate (2 hydraulic winding systems max.).

- Different combinations thanks to removable plates.

- Coil diameter adjustable by support.

- Easy coil extraction thanks to retractable plates and conical supports adjustable according to diameter.

Technical characteristics

| Model |

| Coupling |

| Dimensions (L x W x H) |

| Weight |

| Option winding system : Maximum pressure |

| Option winding system : maximum hydraulic flow |

| Plate for plain wires |

| Plate for dripping hose |

| DEROULMATIC PX |

| 3-point category 1 |

| 1,61 x 0,91 x 1,64 m |

| 126 kg to 247 kg |

| 200 bar |

| 50 L/min |

| Ø Inner of hose : from 380 mm up to 620 mm Ø Outer maximum of hose : 800 mm |

| Ø Inner of hose : from 285 mm up to 640 mm Ø Outer maximum of hose : 910 mm Maximum height of hose : 350 mm |