Skip to main content

Forestry mulching heads with mobile hammers for skid steer

The Designed to mulch grass, bushes and branches between 5-6 cm diameter.

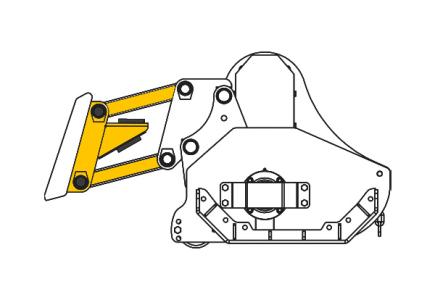

After developing a wide range of forest shredders for excavators and tractors, the RABAUD company expands its offering wth a model of a forest shredder on a compact loader, the XYLOR SK.

Its adaptation to a loader of 50 to 90 HP allows it to work in challenging conditions such as rugged terrain, difficult-to-access areas, or steep slopes over a width of 1.30 meters to 2 meters, depending on the model.

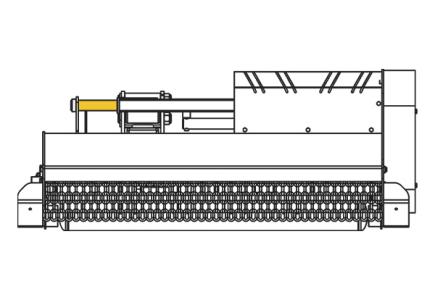

This skid-mounted forest shredder is equipped with mobile hammers, ideal for shredding rather airy vegetation such as grass, bushes, debris, shoots, and branches between 5 and 6 cm in diameter. Its hammers are arranged helically on the rotor, thereby limiting power peaks and preventing premature wear of the hammers.

For a finer shred, this skid-mounted forest brush cutter also has a line of counter-knives.

The Hydraulic Block Control (HBC) system of our forest shredders on loaders optimizes their performance and productivity by regulating the flow, limiting pressure, and enabling a gradual braking of the rotor.

Its wear-resistant steel skids, a cast iron motor protected by a robust housing, and its front protection by a chain curtain make these skid-mounted forest shredders highly robust machines.

Its adaptation to a loader of 50 to 90 HP allows it to work in challenging conditions such as rugged terrain, difficult-to-access areas, or steep slopes over a width of 1.30 meters to 2 meters, depending on the model.

This skid-mounted forest shredder is equipped with mobile hammers, ideal for shredding rather airy vegetation such as grass, bushes, debris, shoots, and branches between 5 and 6 cm in diameter. Its hammers are arranged helically on the rotor, thereby limiting power peaks and preventing premature wear of the hammers.

For a finer shred, this skid-mounted forest brush cutter also has a line of counter-knives.

The Hydraulic Block Control (HBC) system of our forest shredders on loaders optimizes their performance and productivity by regulating the flow, limiting pressure, and enabling a gradual braking of the rotor.

Its wear-resistant steel skids, a cast iron motor protected by a robust housing, and its front protection by a chain curtain make these skid-mounted forest shredders highly robust machines.

On video : Forestry mulching heads with mobile hammers for skid steer

Main Features

- Can be mounted onto skid steer loaders from 50 HP up to 90 HP.

Universal fixed coupling (SAE J2513). - Helical rotor with a set of mobile hammers and counter-knives fitted in ”U-shape” for the best crushing.

- Cast-iron gear hydraulic motor with drain line.

- HBC system (Hydraulic Block Control) allowing the hydraulic flow regulation, limits the pressure and allows rotor progressive braking.

- Side drive by belts.

- Casing for the hydraulic motor.

- Rear roller-feel adjustable in height Ø 165 mm.

- Support pads with interchangeable and anti-wear material.

- Front protection with chains to prevent projections.

Technical characteristics

| Model |

| Skid steer loader power |

| Rotor type |

| Number of hammers |

| Counter-knives line |

| Crushing width |

| Average grinding Ø |

| Helical rotor |

| Rotor Ø (without/with tools) |

| Size of gear motor |

| Drain line |

| Drive |

| Oil flow |

| Maximum pressure |

| Dimensions (L x W x H) with swinging hitcht |

| Weight |

| XYLOR 1400 SK |

| From 50 HP up to 90 HP |

| Mobile hammers |

| 14 |

| 1 line |

| 1400 mm |

| 50 – 60 mm |

| Yes |

| 140 / 400 mm |

| 31 cm³ |

| Yes |

| 3 belts |

| 65 L/min recommended 150 L/min maxi. |

| 200 bar |

| 1,37 x 1,69 x 0,77 m |

| 665 kg |

| XYLOR 1600 SK |

| From 50 HP up to 90 HP |

| Mobile hammers |

| 16 |

| 1 line |

| 1600 mm |

| 50 – 60 mm |

| Yes |

| 140 / 400 mm |

| 41 cm³ |

| Yes |

| 3 belts |

| 90 L/min recommended 150 L/min maxi. |

| 220 bar |

| 1,37 x 1,89 x 0,77 m |

| 690 kg |

| XYLOR 2000 SK |

| From 50 HP up to 90 HP |

| Mobile hammers |

| 22 |

| 1 line |

| 2000 mm |

| 50 – 60 mm |

| Yes |

| 140 / 400 mm |

| 56 cm³ |

| Yes |

| 3 belts |

| 110 L/min recommended 240 L/min maxi. |

| 220 bar |

| 1,37 x 2,29 x 0,77 m |

| 790 kg |