Skip to main content

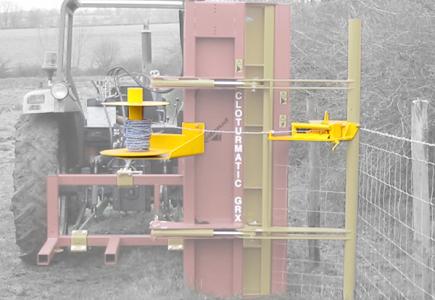

Wire netting unwinding machine : CLOTURMATIC GRX

Wire netting unwinding machine for any sort of wire netting (knotted, welded and multitwisted) up to 2.50m. Ideal for fencing the road sides, demarcating properties…

An indispensable solution to ease your wire fence installation work, the tractor-mounted wire fence unroller CLOTURMATIC GRX.

This unroller enables the creation of enclosures or the securing of road edges.

Available in 2 tractor models, this tool can unroll tied, welded, or multi-twisted wire fences up to a height of 2.50 meters and a diameter of 800 mm, depending on the model.

Loaded on a platform, the wire fence roll unrolls vertically as the tractor advances, allowing for clean and effortless work.

The wire fence unrolling machine is equipped with a hydraulic tensioning system, operated in the cabin by the operator, pressing the fence along the posts for a perfect tension, even on uneven terrain.

A hydraulic holding clamp system maintains tension and prevents any unwinding during roll junction or nailing operations, ensuring a consistently taut fence.

Mechanization of stapling is made possible by an optional pneumatic compressor supplying a nailer.

For even more versatility, this wire fence unroller offers, through an option, the possibility of unrolling 1 or 2 rows of barbed wire above.

Versatile, these wire fence unrolling machines save time and effort in your fence projects, whether they are small or large in scale.

This unroller enables the creation of enclosures or the securing of road edges.

Available in 2 tractor models, this tool can unroll tied, welded, or multi-twisted wire fences up to a height of 2.50 meters and a diameter of 800 mm, depending on the model.

Loaded on a platform, the wire fence roll unrolls vertically as the tractor advances, allowing for clean and effortless work.

The wire fence unrolling machine is equipped with a hydraulic tensioning system, operated in the cabin by the operator, pressing the fence along the posts for a perfect tension, even on uneven terrain.

A hydraulic holding clamp system maintains tension and prevents any unwinding during roll junction or nailing operations, ensuring a consistently taut fence.

Mechanization of stapling is made possible by an optional pneumatic compressor supplying a nailer.

For even more versatility, this wire fence unroller offers, through an option, the possibility of unrolling 1 or 2 rows of barbed wire above.

Versatile, these wire fence unrolling machines save time and effort in your fence projects, whether they are small or large in scale.

On video : Wire netting unwinding machine : CLOTURMATIC GRX

Main Features

- Unwinds netting rolls wire from 0 up to 2.50 m height (on GRX 8025) and up to 800 mm diameter.

- Barbed wire uncoiled for 1 or 2 rows above the wire netting.

- Hydraulic stretching system for the wire netting.

- Clamp for maintaining tension when fixing or joining rollers.

- Loading platform for putting up the wire netting roll.

- Air nailing pistol with stainless steel or galvanized staples (in option).

- Wire netting always clean and put effortlessly, as the unwinding is made in vertical position.

- Many options:

– 2-way dual acting valve,

– Air nailing pistol,

– Air compressor for the nailing pistol,

– barbed wire unroller (maximum 2).

Technical characteristics

| Model |

| Wire netting roll diameter |

| Roll height : without barbed wire |

| Roll height : with 1 barbed wire strand |

| Roll height : with 2 barbed wire strand |

| Dimensions (L x W x H) |

| Weight |

| Drive |

| Coupling |

| GRX 4020 |

| from 0 up to 400 mm |

| 2.00 m max. |

| 1.52 m max |

| 1.37 m max |

| 1,83 x 1,90 x 2,27 m |

| 645 kg |

| Tractor hydraulic pump with hydraulic hoses or PTO 540 rpm – flow 34 L/min. |

| Tractor N°2 3-point hitch with removable pins or Hitch for other carriers Tractor from 80 or 100 HP |

| GRX 8025 |

| from 0 up to 800 mm |

| 2.50 m max |

| 1.52 m max |

| 1.37 m max |

| 2,21 x 1,96 x 2,81 m |

| 985 kg |

| Tractor hydraulic pump with hydraulic hoses or PTO 540 rpm – flow 34 L/min. |

| Tractor N°2 3-point hitch with removable pins or Hitch for other carriers Tractor from 80 or 100 HP |